Be sure to get in contact for help along with your waste, recycling and segregation requirements. We stay up for hearing from you

Tractive Electric power has a wide array of battery powered tractive tug models, to fit your business’s unique demands. Created to boost productivity, improve wellbeing & security and handbook handling challenges in a office.

Our Web site utilizes cookies to tell apart you from other end users of our Site. This aids us to offer you a good encounter if you search our Web-site in addition to allows us to further improve our web page.

MegaTough pickup enamel are built to resist the harshest baling problems and provide lengthy service life

The staggered belt roll structure permits any free hay below or guiding the belts to get returned for the pickup and into the baler. This style and design aids to circumvent buildup with the entrance in the baler, which could cause hay decline and belt or splice harm.

The loop region is chilly solid, which makes it exceptionally wear resistant from the coupling location, resulting in an exceptionally very long cycle everyday living.

The balers promptly minimize the waste material in a price-successful way to assist you improve interior logistics. Our reputable methods are created for continuous infeed and automatic vertical or horizontal strapping with adjustable wire inbound links for optimal output.

A large-potential baler with a sizable feed opening to easily accomodate bulky containers and expandable plastics.

Depending on earlier expertise with vertical balers, which can be mounted for the Valamar lodges on Rab Island, they select a fully automatic baler for their most significant tenting resort.

“A fully automatic horizontal baler” may possibly sound just like a huge piece of apparatus supposed only for municipalities or recycling facilities. However, horizontal balers appear in various sizes and because of good structure and present day engineering a horizontal baler can be extremely compact.

Incoming hay then feeds in between the bale as well as decreased gate roll. Hay is tightly compressed into smooth, dense levels as it enters the bale.

A little sq. baler (Intercontinental design 435) The first kind of baler makes tiny sq. bales. These bales are rectangular-shaped "sq." bales. This was when essentially the most widespread method of baler but is considerably less common today. It's mostly used on tiny acreages wherever large tools is impractical and hay generation for compact operations, specially horse entrepreneurs who may not have access to the specialized feeding equipment utilized for bigger bales.

The fork is then get more info clamped down through the major of the bale, and the bucket is lifted Using the bale in tow. Grab hooks mounted over the bucket of the tractor are One more Device employed to take care of spherical bales, and can be achieved by a farmer with welding skills by welding two hooks as well as a hefty chain to the skin best of the tractor front loader bucket.

We all want dependable, sq.-shouldered bales — but with operation and field ailment discrepancies, we don't all set up hay the exact same way. No matter if you are baling high-moisture hay (also referred to as baleage or silage), dry hay, cornstalks or a mix, Vermeer includes a hay baler for every type of operations in a variety of dimensions to maximize your productiveness and assistance create the highest quality hay.

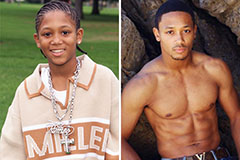

Romeo Miller Then & Now!

Romeo Miller Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now!